What is cross-threading?

- Cross-threading occurs when the first external thread crosses the internal thread in such a way that the thread contacted on one side of the internal thread is not on the same revolution as the thread contacted on the opposite side.

There are two types of external threaded fasteners

Screws - intended for use with a pre-formed internal thread or to form its own thread (self-tapping screws)

Bolts - intended for use with a nut or threaded hole to create a clamping force

Screws and bolts have external threads that are mated together with the internal threads of nuts and tapped holes.

2 types of cross-threading: Parallel or Angular

Crossing-threading is a very common failure when working with any threaded fasteners. Cross-threading occurs when the threaded fastener (bolt, screw) is received into a threaded nut or hole wherein the threads are not in proper alignment.

There are two main types of cross-threading:

Angular cross-threading

Parallel (axial) cross-threading

Angular Cross Threading

During tread mating, one common failure is called angular cross-threading, often called cross-threading for short.

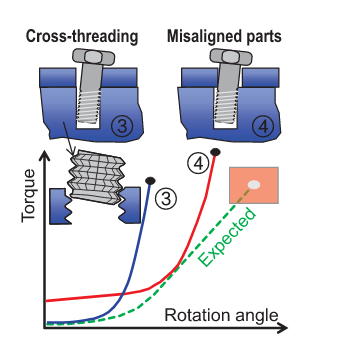

Angular cross threading occurs when the bolt enters the threaded part misaligned angularly, the threads engage incorrectly and as the bolt is tightened, the threads of the bolt and/or nut fail by shearing.

This cross-threading is the result of the threads of the two members trying to engage with at least 1/2 pitch or revolution out of alignment. When this happens, the parts are no longer compatible and the threads wedge up upon rotation. If you continue to rotate (screw) the threads they become angularly misaligned and structurally damaged.

Parallel Cross Threading

Parallel cross threading is a more subtle form of cross threading and occurs when the thread run-up of the two parts is twisted together during initial mating. Unlike angular cross threading, parallel cross-threading can occur even without angular misalignment, as this failure is usually induced by excessive screw rotation speed during insertion.

This occurs when the tread patterns don’t match up perfectly.

Commonly happens with power tools as the threads get “over-torqued” and the threads no longer align properly

How to avoid cross threading

The initial thread mating is the most critical time to avoiding cross threading and jamming. To avoid angular cross-threading, the external thread must not be allowed to cross under the crest of the internal thread so that the screw is aligned with the part that it is joining.

3 simple steps to avoid cross-threading or stripping screws/bolts:

Check and clean bolt/screw as needed

Insert fastener and screw in opposite direction (like you’re unscrewing it) and keep turning it backwards until you hear a click sound. Once you hear this click (or feel a pop), this means that both the internal and external threads or male and female parts are in proper alignment and ready to be tightened.

After hearing the click, finger tighten until it goes in smoothly, before using tools to torque to speck.

It’s easier to cross thread when using tools since you have more power and less accuracy

Fine vs Coarse threads & cross-threading

Coarse threads are more durable and less likely to cross-thread and strip.

Fine threads damage easier and are easier to cross-thread. When working with fine threads, be extra careful.

Jesse is the Director of Pedal Chile and lives in La Patagonia. Jesse has a Master of Science in Health and Human Performance and a Bachelor of Science in Kinesiology. Hobbies: Mountain biking, bicycle commuting, reading, snowboarding, researching, and sampling yummy craft beers.

More articles from Pedal Chile

Sources

Gallagher, B., Silva, M. J., & Ricci, W. M. (2014). Effect of off-axis screw insertion, insertion torque, and plate contouring on locked screw strength. Journal of orthopaedic trauma, 28(7), 427–432. https://doi.org/10.1097/BOT.0000000000000042

Jia, Zhenzhong, et al. “A Survey of Automated Threaded Fastening.” IEEE Transactions on Automation Science and Engineering, vol. 16, no. 1, Jan. 2019, pp. 298–310, 10.1109/tase.2018.2835382. (image source for image right of figure 2)

Nicolson, Edward J. and R. Fearing. “Compliant control of threaded fastener insertion.” [1993] Proceedings IEEE International Conference on Robotics and Automation (1993): 484-490 vol.1. (image source for figure 2)

Wikipedia. “Screw Thread.” Wikipedia, 30 Apr. 2020, en.wikipedia.org/wiki/Screw_thread.